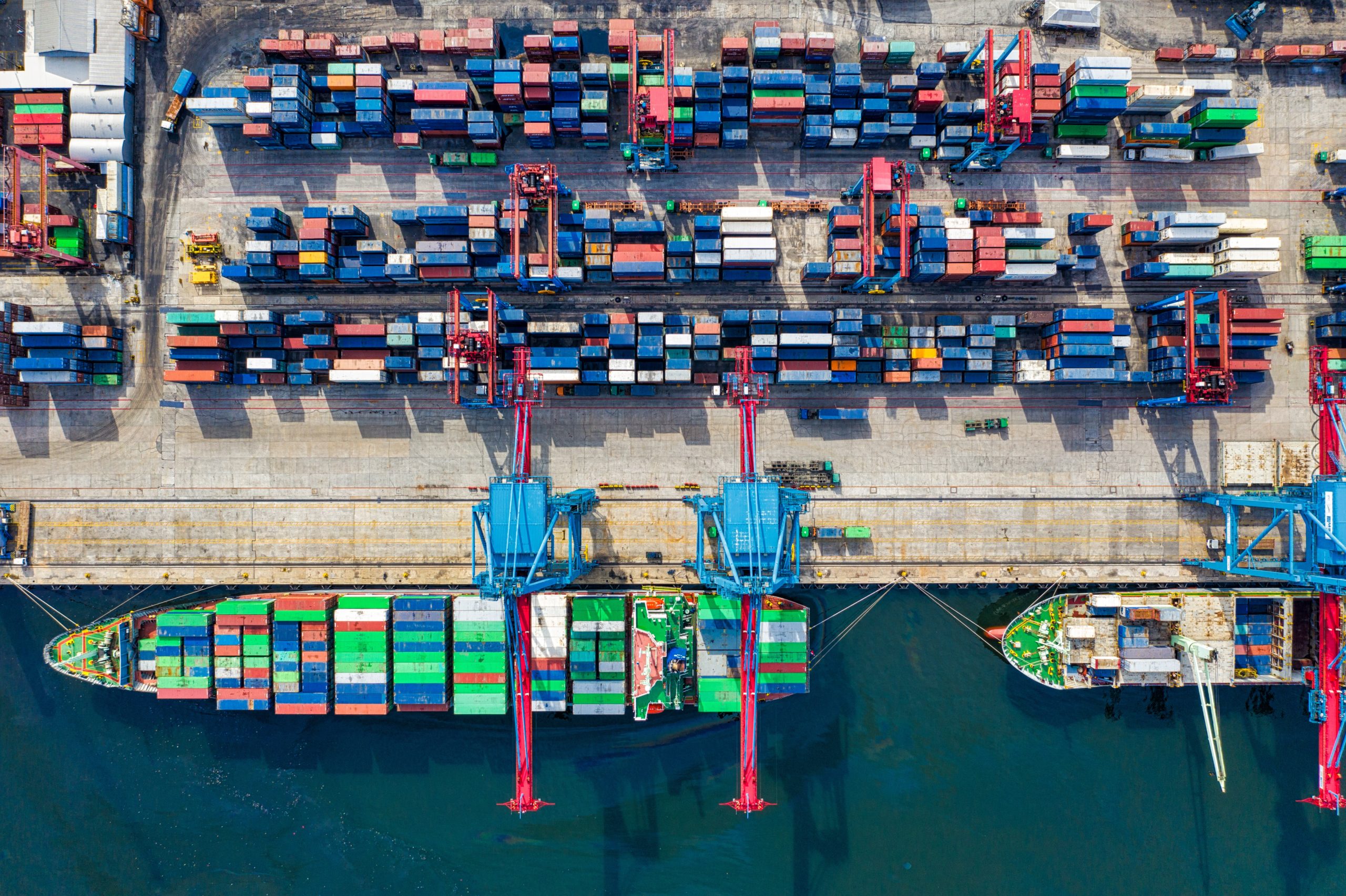

The utilization of shipping containers is a vital piece of the Showbest process. While we’re based in Richmond, VA, the global economy and manufacturing trends directly impact our customer lead times and material costs. Currently, there is an international container shortage. In this blog, we’ll cover how this is affecting Showbest and the proactive steps we’re taking to mitigate the impact to our clients.

Why is there a Container Shortage?

When factory production halted for much of the world in the spring of 2020 as the pandemic spread, cargo ships around the world were forced to cancel their routes. As a result, containers remained in port in North America and Europe. Now, manufacturing facilities in Asia, North American, and Europe, are working at capacity to meet an ever-growing pent up demand. However, container ships are still in the process of being recommissioned and re-routed to align with increased production. In the interim, there are currently not enough container ships to carry materials and goods at the rate of production.

But how does this affect consumers? This shortage is causing historic spikes in shipping rates as exporters are scrambling to find containers. For example, in March of 2020, the rate of shipping a container from Asia to North America and Europe was as low as $1,200. Utilizing the same container now costs approximately $6,000, a 300% increase. Showbest’s average container rate of $4,200 has nearly tripled to $11,000.

Along with the rising costs of shipping containers due to a shortage, businesses also have seen heavy delays caused by congested shipping ports. According to Sea-Intelligence, only 50.1% of container trading vessels arrived on time during Q4 2020, a historic low since 2011. With many containers still in port, crowded terminals have slowed the entire process. And, with less air travel as a result of the pandemic, air freight is another dwindling option.

Showbest’s Expertise in Sourcing and Importing

Showbest has been manufacturing fixtures for over 50 years. We have historical knowledge and utilize best practices when handling supply chain challenges. Currently, we are:

-

- Utilizing our established material vendor relationships to assess every option to ensure our clients’ requested materials arrive as quickly and as economically as possible.

- Maximizing our purchasing leverage on behalf of our clients. As a one “one-stop-shop” our clients can consolidate their imports from multiple overseas manufacturers, allowing for less logistical headaches and larger bulk pricing based on volume.

- Working to augment the traditional shipping process by utilizing other transportation methods domestically in conjunction with shipping containers.

While we can’t control global shortages and delays, we can guarantee that we will do everything possible to deliver for our clients. Whether that’s using domestically sourced wood and materials or working overseas with our partners to expedite your project, our streamlined communication allows us to continue to help our clients open storefronts and restaurants across the country. If you have any questions or are ready to start your new project, Showbest is happy to help every step of the way!